कृषि में बायोडिग्रेडेबल पॉलिमर के अनुप्रयोग और उपयोग

In the agriculture sector, biodegradable polymers have become more popular in recent years. In recent years, biodegradable polymers have attracted a lot of interest as a potential replacement for conventional plastic materials in agricultural applications.

The impact of plastic trash on land and waterways is lessened by these materials fast and safe environmental breakdown. The use of biodegradable polymers in agriculture has various benefits, including enhanced crop yields and soil health, in addition to reducing waste. Moreover, in the upcoming years, there will be a notable growth in the production of this kind of material.

Why do biodegradable polymers exist?

A polymer that can undergo total degradation under the influence of environmental microorganisms is known as a biodegradable polymer. When a plastic container reaches the end of its useful life and begins to break down as a result of various environmental factors, we say that it is biodegradable. Following biodegradation, this polymer yields compost, CO2 and water, all of which are reabsorbed by the environment.

Origin

The packaging business uses a lot of biodegradable polymers that are derived from renewable resources. This indicates that the carbon atoms in their chains of molecules come from the natural world. This is the phenomenon usually known as possessing a "bio-origin·. The biopolymers used in the bioplastics industry often originate from biobased materials like sugar cane, corn or sugar beet.

Qualities of biodegradable polymers

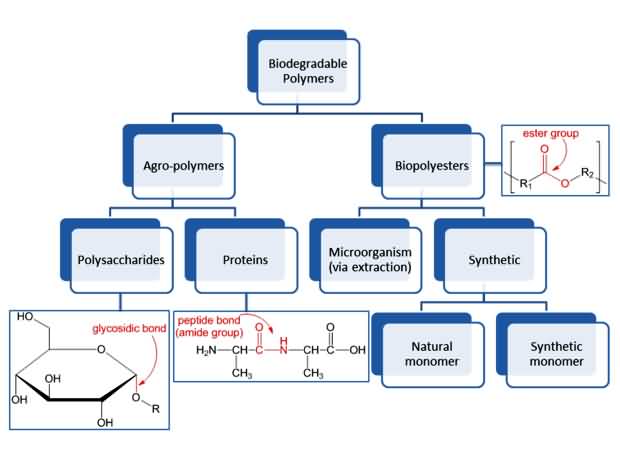

The majority of linkages in biodegradable polymers are ether, amide, or ester bonds. Biodegradable polymers can be broadly classified into two classes according to their synthesis and structure. Agro-polymers, or those made from biomass, are one of these categories. The other is composed of biopolyesters, which can be artificially produced from naturally occurring or manufactured monomers, or they can be generated from microorganisms.

Agro-polymers are composed of proteins, such as whey from animals or gluten from plants, and polysaccharides, such as starches found in potatoes or wood. Glycosidic linkages, which take a hemiacetal of a saccharide and bind it to an alcohol by losing water, are the building blocks of polysaccharides. Amino acids, the building blocks of proteins, have a variety of functional groups. By condensation reactions, these amino acids recombine to generate peptide bonds, which are made up of amide functional groups. Polylactic acid and polyhydroxy butyrate are two examples of biopolyesters.

There are different types of biodegradable polymers that can be classified, into three groups according to their origin.

- Natural polymerssuch as starch, cellulose and proteins

- Modified naturalpolymers

- Synthetic polymerssuch as PLA

Examples

- Polylactic acid (PLA)

- Polyhydroxyalkanoate (PHA)

- Polybutylene succinate (PBS)

- Polyvinyl alcohol (PVA)

- Cellulose Acetate (CA)

- Polyglycolic Acid (PGA)

- Polymer Materials Based on Lignin

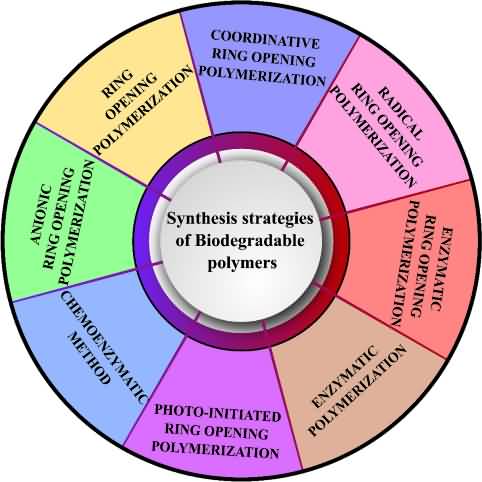

Strategies involved in the synthesis of biodegradable polymers

Biodegradable polymer uses

1. It is Easy to recycle biodegradable polymers: These polymers not only decompose faster when discarded but can also be easily recycled using an organic method. Recycling helps to reduce landfill waste, and the recycled bio-waste can also be used as compost or as a renewable energy source for biogas production.

2. The amount of waste generated is reduced: Biodegradable plastic degrades in a matter of months, depending on the material used to make it and the method of disposal.

3. Reduction in carbon Emission: One of the most important benefits of using biodegradable polymers to produce plastic bags is the significant reduction of carbon emissions during the production process instead of conventional plastic.

4. Greenhouse gas emissions are reduced: As the biodegradable polymer is used instead of conventional plastics, greenhouse gas emissions are reduced.

5. Reduced use of petroleum: Oil is an essential component in the production of traditional polymer. When you consider the amount of waste generated during refining and even during the extraction of oil from the earth, it is no surprise that petroleum harms the environment.

6. They consume less energy during their manufacture: Although the initial investment may be marginally higher, biodegradable plastics need less energy in the long run and require the reprocessing of fossil fuels to produce polymers.

Biodegradable polymer applications

There has been a recent push for research into creating materials that are more environmentally friendly and sustainable. In this regard, biodegradable polymers have emerged as one of the most effective substitutes for traditional plastics in achieving this goal.

Applications in Agriculture

There are many products in the agricultural sector in which biopolymers can play a role. Some of these applications can be films or tutors, where, as they are intertwined with the crops, we would avoid having to harvest them later on. Among the natural polymers utilized in controlled release systems include lignin, starch, chitin, cellulose, and alginic acid. Biopolymers are utilized in marine agriculture to create fishing nets and ropes. Using biodegradable materials in mulching and low-tunnel cultivation is a viable way to improve sustainability and ecologically friendly agriculture practices. Throughout their useful lives, agricultural films buried in the soil are subject to aging and degradation, therefore they must possess a few certain qualities.

Applications in Medicine

Biodegradable polymers are currently being used in orthopaedic and vascular surgery for surgical implants as well as simple membranes. Biodegradable polyesters are commonly used as porous structures in tissue engineering due to their high strength and adjustable rate of disintegration. These can also be employed as absorbable sutures or as implantable matrices for the controlled release of medications within the body. Gelatin is a naturally occurring polymer that is utilized in the production of biodegradable hydrogels as well as coatings and microencapsulation for different medications in biomedical applications.

Applications in Packing

Another significant application for biodegradable polymers is packaging. Biodegradable polymers are frequently utilized to decrease the amount of trash produced. Biopolymers have traits like low temperature and air permeability, among others. PLA Its permeability to oxygen and water vapor is medium. It is applied to packaging materials like bottles, cups, and films. Soft biodegradable packaging also uses PCL.

Applications in Other Fields

1. Automotive: By using bioplastics and bio composites, the auto industry hopes to create lighter vehicles.

2. Electronics: In electronics applications, PLA and kenaf are utilized as a composite. The Fujitsu business has already employed PLA to create a computer enclosure.

3. Construction: The cushioning and paving stones of the carpet are made of PLA fiber. Because it is less flammable than synthetic fibers, it provides greater security.

Conclusion

The use of biodegradable materials in packaging, agriculture, medicine and other fields has become increasingly popular in India in recent times. Biocomposites, or materials made of biodegradable polymers, are particularly intriguing. Plastics are primarily composed of polymers, which are used in an increasing number of applications. Consequently, a great deal of research is being done on creating novel polymer composites using naturally existing components and changing conventional materials to make them more user friendly. Biodegradable polymer materials can contain a variety of biological components, the most popular being starch and fiber that have been derived from different kinds of plants.

References

- Tertyshnaya, Y.V. Podzorova, M.V, Varyan, I.A, Tcherdyntsev, V.V, Zadorozhnyy, M.Y, Medvedeva, E.V. Promising Agromaterials Based on Biodegradable Polymers: Polylactide and Poly-3-Hydroxybutyrate. Polymers

- https://primebiopol.com/los-3-tipos-de-bioplastico-que-debes-conocer/?lang=en

- https://www.embibe.com/exams/biodegradable-polymer/

- Takiyama E., Fujimaki T. In: Biodegradable Plastics and Polymers. Doi Y., Fukuda K., editors. Volume 12. Elsevier; Amsterdam, The Netherlands: 1994.

Authors:

Pradeesh Kumar Thangavel

Assistant Professor (Agronomy), Department of Agronomy,

VIT School of Agricultural Innovations and Advanced Learning (VAIAL),

Vellore - 632 014, Tamil Nadu, India

Corresponding Author E-mail:

This email address is being protected from spambots. You need JavaScript enabled to view it.