धान के मूल्य वर्धित उत्पाद पोहा (फ्लेक्ड राइस) की उत्पादन तकनीक

Paddy (Oryza sativa) is second largest major cereal crop which produces starchy seeds. Rice is a source of nourishment for more than half of the world’s population. iT is one of the leading food crops of the world. The paddy is converted into edible form of the rice for which the paddy undergoes several post harvest operations.

Rice flakes are prepared from paddy. It is also popularly known as "Poha". It is a fast moving consumer item and generally eaten as breakfast item. It can be fried with spices and chilly to make hot and tasty food item or milk / curd is mixed with it and then eaten.

Flaked rice is a thin crispy snack. It is mainly used as Breakfast cereal. It has high content of fiber & calorific value. It can easily be soaked in cold or hot water.

Fig. 1: Raw material paddy grain and its value added product flaked rice (poha)

Processing methods of flaked rice

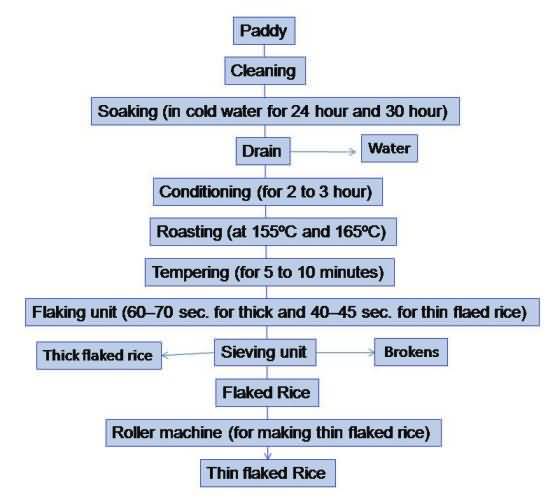

The process of product (flaked rice in two different size ) development is depicted in the flow diagram shows the steps involved in process for preparation of flaked rice. Raw paddy was soaked in the water for 24 to 30 hours at a room temperature to increases its moisture content up to 30 to 32 %.

This was followed by complete removal of water from soaking tank and the soaked paddy was conveyed through a 5kg cloth carry bags into the hopper of the paddy roaster operated at the highest temperature about 172 - 175ºC for a short period of time about 35 to 40 seconds in fine sand.

The process result in drying of husk with its internal moisture content in the range of 17 to 19 % yielding roaster paddy that was immediately conveyed to the rice flaked machine operating at 200 rpm by 3 HP electric motor.

The machine resulted in the formation of flaked rice (45 to 55 seconds for thick size flaked rice and about 60 to 70 seconds for thin flaked rice), that as passes further cleaned in a cleaning unit to separate any broken and husk from flaked rice.

Soaking and Conditioning

Soaking is done in metal drum or cement tank for about 10-12 hours, after which the water is drained. For larger processors, soaking time ranges from 2-24 hours. Many large scale processors have replaced the cement tank with vertical metallic tanks where the paddy is fed through bins from the top.

After the given soaking time, the water is drained and paddy is conditioned for 2-3 hours within the soaking tank or after heaping or spreading on a cement floor. The moisture content of soaked paddy reaches 25-33 %, depending on climatic condition and the method of soaking and conditioning.

Roasting

Roasting, which can be performed with or without sand, is strenuous, labor intensive, and costly manual operation that requires skill and fine judgment to determine the appropriate termination point.

Even a slight shift from the optimal roasting conditions may entail loss of yield caused by puffing of grain during roasting or breakage during flaking due to under roasting. In Maharashtra and Tamil Nadu, paddy is roasted in sand, where as in Karnataka it is roasted in fine silt medium.

In medium and large scale industries, roasting is usually performed by continuous roaster using a sand medium. The partial gelatinization of soaked paddy is achieved from roasting at 110-180ºC for 10-60 seconds. The soaked paddy is fed to the roaster by means of belt conveyor or by manually feeding the hopper.

A medium scale processor may have one such roaster and five edge runner. Large processors would simply have more roasters and flaking units. Some of these larger processors would simply have roaster and flaking unit.

Some of these larger processors have a pre-cleaning facility, whereas in other place the raw paddy is soaked and the floating chaff and immature paddy are collected manually.

Fig. 2: Process flow chart for preparation of flaked rice

Fig. 3: Roaster machine for flaking process

Sieving and Conditioning

The roasted paddy is fed to the flakers, whereas, in medium and large scale system it is moistened and conditioned to obtained different types of flakes, such as thick (~1 mm), medium (~0.6 mm), thin (0.55-0.3 mm) and very thin (˂0.3 mm).

For the largest processors that operate the continuous type of roasters, the sand roasted paddy is sieved in order to remove the adhering sand and impurities.

Flaking

Edge runners are batch type flaking machines with the capacity to flake 50, 100, and 150 Kg/hr of paddy. In edge runners, the paddy is pressed in between the body of the edge runner and flaking roller. The husk and bran come out through the perforated mesh at the base of the edge runner.

The remaining husk parts and bran that continue along with the flaked rice are cleaned by manual winnowing or by using a sieving shaker. After completion of flaking, the flaked rice is scooped out by hand and collected in plastic buckets.

Fig. 4: Edge runner machine

In some places. The flaked rice obtained from the edge runner is again pressed and flattened in roller flakers to further reduce the thickness. In roller flakers, it consist of two cylindrical rollers. The roasted paddy is shelled and polished and then fed in between the roller, in which it is pressed and flattened.

The reduction in thickness is accomplished by passing the paddy through the set of roller in sequence and passing the flakes for further flattening. The gap between the rollers is maintained by pressures. In medium and large scale industries, different types of flakes are produced.

The end products are categorized according to the thickness of the flakes.

Fig. 5: Roller machine for making thin flaked rice

Sieving and packing

The flaked rice is sieved in a sieve shaker in order to separate small, broken, powdered material and lumps. The thick flaked rice requires drying (shade drying) in order to reduce the moisture content before packing. After this, the flaked rice is packed directly into polyethylene bags.

Different packing systems are in practice, depending on the requirements of the local market and the quality and type of flaked rice. The shelf life of the thick type of flaked rice is less than the medium and thin type flaked rice as it contains more moisture and undergoes less polish than the other grades.

Fig. 6: Sieving machine

Final product

Generally 65-70% of yield is obtained in the field depending on variety, quality of paddy, processing, condition and the type of flaked rice processed. Different states are using different paddy variety such as Mahamaya in Chhattisgarh and Maharashtra and Kranti in Madhya Pradesh for flaked rice prepared .

Fig. 7: Thick sized flaked rice prepared from different varieties of paddy

Benefits of Flaked rice in diet

Controls of blood Sugar levels

Poha is considered a good meal for diabetics. Being rich in fibre, poha promotes a slow and steady release of sugar into the blood stream, thereby preventing any sudden spikes in blood sugar levels.

A Good source of healthy carbohydrates

Poha is made up of 76.9 per cent of carbohydrates and about 23 per cent of fats. Hence, it's a great breakfast food as these healthy carbohydrates provide energy to the body to carry out its daily functions.

Easily digestible

Poha will never cause bloating and will also keep you full for longer. Poha is also light on the stomach and can be easily digested. Therefore, it can either be had as the first morning meal or as a light evening meal.

Rich in Iron

Lactating or pregnant women are often advised to eat softened poha, as these women are at high risk of gestational anaemia. This is because the production process of poha requires the rice to pass through iron rollers. The flattened rice retains some of the iron from the process and are hence considered to be rich in iron.

Low in calories –

Poha is also quite low in calories. One bowl of cooked vegetable poha has just around 250 calories, along with a number of essential vitamins, minerals and antioxidants too due to the presence of curry leaves in it. If you add some peanuts to the mix, it raises the number of calories in the meal, but if you're watching your weight, you may want to skip the peanuts.

Hence, eating Brown rice which is less processed and contains higher amount of fibre, low amount of carbohydrates. Coming to Rice Poha, it is considered healthy as it is light in terms of cooking, is easily digested, and it slightly less processed. White rice is less healthy than brown rice because it has less fiber.

However, nutritionists recommend poha as one of the healthiest Indian breakfasts. Poha is a wholesome meal. It is a good source of carbohydrates and iron, rich in fibre, a good source of antioxidants and essential vitamins and is gluten free. It is known to be good for those who have diabetes, skin and heart problems

Authors

Rahul Dahare

Qtr. No. C/1, Krishak Nagar, IGKVV,

Jora, Raipur, Chhattisgarh. 492012.

Email :