23 Sep Filter used in chinese circular carp hatchery

चीनी सर्कुलर कार्प हैचरी में प्रयुक्त फ़िल्टर

Jham La

The filtration system used in Chinese circular carp hatcheries is a fundamental component that ensures optimal water quality and successful fish breeding, hatching, and larval rearing.

These hatcheries rely on a continuous flow of water, which is efficiently filtered to remove debris, prevent the loss of eggs and larvae, and maintain suitable environmental conditions for the developing fish.

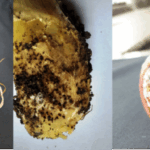

At the heart of the filtration process is a circular incubation or hatching tank, typically constructed with two chambers. The inner chamber is enclosed by a fine mesh or nylon bolting cloth, which acts as a filter to retain eggs and larvae while allowing water to pass through.

Water is introduced through multiple inlets (often equipped with duck-mouth openings) to create a gentle, uniform current that keeps eggs in suspension and prevents them from settling or clumping. The filtered water exits via the inner mesh, ensuring that only clean water returns to the system or is discharged.

This design not only filters out solid waste but also helps maintain high oxygen levels and prevents the buildup of harmful metabolites, both of which are essential for high hatching rates and healthy fry development (Boyd and Pillai, 1985).

The efficiency and simplicity of this filtration approach make it a cornerstone of the Chinese circular carp hatchery system.

Different types of filter

Several types of filters are integrated into Chinese circular carp hatcheries to maintain water quality, support egg and larval development, and ensure efficient hatchery operation. The main filtration approaches include:

- Mesh Screens/Fine Mesh Chambers:

The most common filter is a fine mesh (such as nylon bolting cloth or regulated mesh) that forms the inner wall of the incubation tank. This mesh allows water to flow out while retaining eggs and larvae, preventing them from escaping or being lost with the outflow. - Mechanical Filtration:

In some systems, additional mechanical filters (such as gravel or sand beds) are used in external filtration or settling tanks to remove solid debris and particulate matter from the water before it re-enters the hatchery circuit. - Biological Filtration:

Biological filters may be incorporated, especially in more advanced systems, to facilitate the breakdown of ammonia and other metabolites. These filters typically use gravel, sand, or other porous media that provide surface area for beneficial bacteria. - Settling and Filtration Tanks:

Settling tanks or separate filtration chambers are sometimes used to allow solids to settle out before water is recirculated or discharged. These can be simple brick or concrete-walled sections filled with sand or gravel for improved filtration.

Maintenance and Cleaning of Filters

Routine backwashing

Routine maintenance focuses on regular cleaning of the fine mesh screens that form the inner chamber of the hatchery tank. After each hatching cycle or whenever debris accumulates, the mesh is cleaned using brushes with long handles from the side of the inner chamber to prevent clogging and maintain continuous water flow.

This process is essential for avoiding water choking and ensuring that only clean, oxygenated water passes through the system, supporting high hatching rates and healthy larval development. Such cleaning practices effectively substitute for mechanical backwashing in these hatcheries (Moretti et al., 1999).

Replacement of filter media

In Chinese circular carp hatcheries, filter media—typically fixed nylon screens or mesh—are critical for trapping eggshells and debris while allowing continuous water flow during incubation. Over time, these screens can become clogged with eggshell fragments and organic matter, which impedes water circulation and reduces oxygen levels, potentially endangering hatchlings.

To maintain optimal conditions, the clogged central screen should be carefully removed and replaced with a new one, ensuring minimal disturbance to the incubating eggs; regular brushing and hosing of the screen between replacements also help keep the system clean and efficient.

This maintenance ensures that water quality and flow remain consistent throughout the incubation process (Jhingran and Pullin. 1985).

Biofilter conditioning and cleaning without killing bacteria

Maintaining the effectiveness of biofilters in Chinese circular carp hatcheries requires careful conditioning and cleaning to preserve beneficial bacteria essential for biological filtration. When cleaning, it is important to avoid using harsh chemicals or chlorinated water, as these can kill the microbial communities responsible for breaking down ammonia and nitrite.

Instead, biofilter media should be gently rinsed with clean, dechlorinated water during routine maintenance, ideally using water from the hatchery system or from a similar source to minimize shock to the bacteria.

This approach helps remove accumulated solids and debris while keeping the biofilter’s biological activity intact, ensuring continued high water quality and supporting healthy carp development (Yusoff et al., 2024).

Advantage

The filters used in Chinese circular carp hatcheries provide several key advantages that contribute to their efficiency and effectiveness:

High Hatching Success: The fine mesh screens and continuous water flow ensure that eggs and larvae are not lost or damaged, resulting in very high hatching rates—often exceeding 95%.

Water Quality Maintenance: Filters remove debris and solid waste, while the continuous flow of water keeps the environment clean and well-oxygenated, reducing the risk of disease and supporting healthy larval development.

Prevents Loss of Eggs and Larvae: The mesh filter retains eggs and larvae within the hatching chamber, preventing them from escaping with the outflow and ensuring high survival rates.

Low Operational Cost: The design is simple and relies on gravity for water movement, minimizing the need for expensive pumps or complex machinery. This makes construction and operation more affordable compared to other hatchery systems.

Ease of Operation and Maintenance: The filtration system is easy to clean and maintain, supporting regular and repeatable hatching cycles with minimal downtime.

Scalability: The system can be easily scaled up to handle large numbers of eggs (millions per batch), making it suitable for commercial-scale production (Das, 2003).

Conclusions

The filter typically a fine mesh screen plays a vital role in Chinese circular carp hatcheries by maintaining water quality and protecting eggs and larvae from debris and mechanical injury while allowing continuous water flow. The filtration system enables efficient removal of eggshells and organic waste, supporting high hatching success rates and healthy fish development. However, regular maintenance and replacement of filter media are necessary to prevent clogging and ensure optimal performance, highlighting the importance of proper technical management in sustaining hatchery productivity and water quality.

References

Bhattacharyya, P., Nandi, K., Sen, D.J. and Saha, D. (2021). Filtration: A mechanical or physical operation to remove debris In‒Vitro/In‒Vivo. World Journal of Pharmaceutical and Life Science. 7,2:52 – 64.

Boyd, C. E., & Pillai, V. K. (1985). Water quality management in aquaculture. CMFRI special Publication, 22, 1-44.

Das, S.K. (2003). Breeding of carps using a low-cost, smallscale hatchery in Assam, India – A farmer proven technology. Aquaculture Asia. 1-10.

Jhingran, V.G. and Pullin. I.S.V. (1985). A hatchery manual for the common, Chinese and Indian major carps. ICLARM Studies and Reviews 11, 191 p. Asian Development Bank, Manila, Philippines and International Center for Living Aquatic Resources Management, Manila, Philippines

Moretti, A.; Pedini Fernandez-Criado, M.; Cittolin, G.; Guidastri, R. Manual on hatchery production of seabass and gilthead seabream. Volume 1. Rome, FAO. 1999. 194 p.

Yusoff, F. M., Umi, W. A., Ramli, N. M., & Harun, R. (2024). Water quality management in aquaculture. Cambridge Prisms: Water, 2, e8.

Authors:

Jham Lal, Harshavarthini M., Basant Singh, Dushyant Kumar Damle*, Reeya Mondal

Late Shri Punaram Nishad College of Fisheries, (Dau Shri Vasudev Chandrakar Kamdhenu Vishwavidyalaya, Durg), Kawardha, Chhattisgarh-491995, India

*Corresponding author email: dushyant.damle@dsvckvdurg.ac.in

Related Posts

………………………………………

Related Posts