कृषि में इलेक्ट्रोसपिनिंग नैनोफिब्रिज के अनुप्रयोग

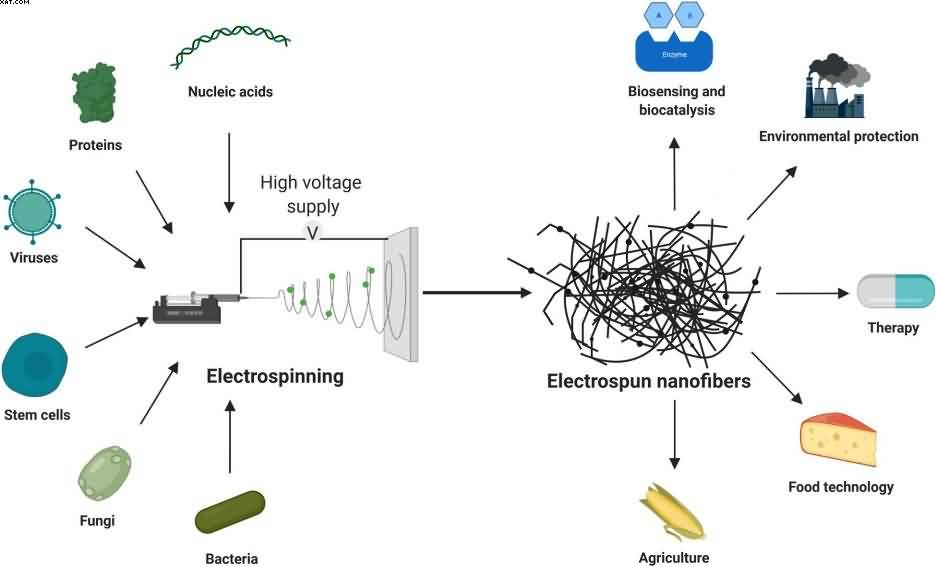

Nanofibres are able to form a highly porous mesh and their large surface-to-volume ratio improves performance for many applications. Electrospinning has the unique ability to produce nanofibres of different materials in various fibrous assemblies. Electrospinning was first patented in the US in 1902. However, the process was largely forgotten until the 1990s.

With interest in the field of nanoscience and nanotechnology, researchers began new investigations of nanofiber production using electrospinning (Seeram et al. 2006). The number of patents and applications for processes and applications based on electrospinning has also grown in recent years.

Types of Electrospinning

Although fibers produced by different electrospinning methods have attracted increasing attention in the field of biomedical applications, challenges persist for the selection of an appropriate method, as well as for optimizing multiple parameters to generate robust cargo loaded nanofibres. Electrospinning techniques can be classified into five categories:

- Blend electrospinning

- Coaxial electrospinning

- Emulsion electrospinning

- Melt electrospinning

- Gas jet electrospinning

Blend electrospinning can be used to develop nanofibres with burst release, while co-axial and emulsion electrospinning can be used to generate core-shell nanofibres that can assist in sustained drug release. Melt electrospinning is a cleaner fabrication method that has been used extensively to produce highly ordered electrospun nanofibres. However, melt electrospinning results in the generation of fibers with a larger diameter (Masumeh Noruzi, 2016).

Application of electrospinning techniques in agriculture

Electrospinning in Pest control

Pest management is not restricted to agricultural land as it also applies to homes and build-up areas. A network of fibers from electrospinning instead of powder or aerosols provides several advantages for controlling and keeping out pests.

The fibrous network may be used as a physical barrier to keep out the pests or it may be loaded with active chemicals. The amount of chemicals needed may be reduced as the fiber matrix protects the loaded chemicals from the environment while slowly releasing them for pest management (Krishnamoorthy et al. 2017).

Electrospun nanofiber with its large surface area is able to effectively release the pheromones for this purpose. Electrospinning may also be used for encapsulating pesticides and it may be useful in keeping airborne pests from landing on the plants.

The mesh of fibers from electrospinning can be easily sprayed and this forms a fibrous network across neighbouring plants. This functions as a physical and chemical barrier against potential pests.

Fertilizer Application

Fertilizers have been added into the solution for electrospinning into fibers. Depending on the polymer carrier and the structure of the fibers, the release rate of the fertilizers may be tailored. A network of fibers is much less likely to be washed away than particles. This will reduce the amount of fertilizer loss by the farmer and at the same time prevent pollution of the waterways due to fertilizer run-offs.

In the dry season, a layer of fertilizer loaded fibers electrospun directly over the top soil may also be used to hold down the soil with the seed in place while waiting for rain to arrive in an exposed dry field. Seeds coated with fertilizers loaded electrospun fibers have been shown to facilitate germination (Zhao et al. 2013).

Pollution control

Agriculture with its use of fertilizers, pesticides, herbicides and fungicides to improve yield of the crops is often a source of pollution and may sometimes be detrimental to the crops itself. Herbicides while meant to reduce growth of weeds, may act against seed germination or seedlings if the water source is contaminated with it.

Pesticides and fungicides residues are always a concern for consumers while excess fertilizers washed into the streams and rivers may disrupt its ecosystem.

Drug Delivery

Electrospun fibers have been tested for drug delivery in various medical applications. A similar strategy may be employed for farm animals. The potential use of electrospun progesterone-loaded zein fibers for estrus synchronization of bovines.

In their study higher concentration of progesterone was found to disrupt fiber production due to increased viscosity. However, even at the lowest tested concentration, the release of progesterone can be sustained over a week with 87% of the hormone released. With higher progesterone concentration, the half-life of the hormone release increases accordingly.

Seed Development

The importance of understanding seed development has led to research using various methods to understand environmental stimuli on root growth. In the use of transparent microfluidic channel for studying root growth, one main challenge is to regulate the temperature on seed development.

Comparing the insulation property of electrospun membranes with cast membranes, the former was able to provide much better insulation for the same thickness. The level of insulation can be controlled easily by varying the duration of fiber deposition which directly impacts membrane thickness. With this, they were able to show the growth rate variation of Arabidopsis seeds at different temperatures (Tiwari et al. 2012).

In-vitro pollen germination

Pollen germination in vitro is useful for determining pollen viability and other in vitro tests. The medium for supporting pollen germination typically comes in the form of liquid or agar gel. Electrospun membrane may be used as a physical support for pollen germination on liquid medium.

Conclusion

Electrospinning is a promising technology for manufacturing nanofibres from the laboratory to industrial level. Nanomaterials possess a large surface area and enhanced porosity, which are advantages for drug delivery and many other biomedical applications.

Electrospinning is the most widely used technique because of its promising results. Electrospun nanofibres have attracted much attention due to their biocompatibility, adhesiveness, sterile nature and their efficiency in diverse applications. Currently, nanofibres are considered suitable platform for wound dressing materials, drug delivery systems, filtration membranes, catalysts for reduction and so on.

References

- Krishnamoorthy, V and Rajiv, S. (2017). An Eco-friendly Top Down approach to Nutrient Incorporated Electrospun Seed Coating for Superior Germination Potential. Journal of Advanced Applied Scientific Research. 21, 187-202.

- Masumeh Noruzi. (2016). Electrospun nanofibres in agriculture and the food industry: a review. J. Sci. Food Agric. 96 (14): 4663-4678.

- Seeram, R, Kazutoshi, F, Thomas, Y and Zuwei, M. (2006). Electrospun nanofibres: solving global issues. Materials Today: Proceedings. 9 (3): 40-50

- Tiwari, J.N., Tiwari, R.N. and Kim, K.S. (2012). Zero-dimensional, one-dimensional, two-dimensional and three-dimensional nanostructured materials for advanced electrochemical energy devices. Prog. Mater. Sci. 57: 724-803.

- Zhao, D, Zhang, Y, Lv, L and Li, J. (2013). Preparation and release of avermectin-loaded cellulose acetate ultrafinefibers. Polym. Eng. Sci. 53: 609.

Authors:

Pradeesh Kumar

Assistant Professor (Agronomy), Department of Crop Management,

Vanavarayar Institute of Agriculture, Coimbatore - 642 103, Tamil Nadu, India

E-mail: